Advanced Materials and Manufacturing

As the world gets smaller, obstacles, challenges and problems often require more refined and precise solutions in advanced materials and manufacturing. Whether exploring nanotechnologies, environmentally sustainable materials, machine learning and biological behavior, textile design, aerospace manufacturing or renewable energy sources, our researchers are grappling to discover the complex solutions that will advance the technologies of the future.

Public Impact Research

Georgia Southern innovations in advanced materials and manufacturing delivers applied research and development knowledge and solutions for major national initiatives and regional industry while creating a diverse, highly skilled, and capable workforce to help foster economic growth and development.

Faculty Expertise

Materials Engineering, Processing, and Characterization

Areas of faculty expertise in material science and engineering are metallurgy, polymers, composites, biomaterials, and nanomaterials. Metallurgical properties are characterized from samples created in the foundry and then heat treated to improve properties. Soft polymer composites are engineered materials for flexible electronics, energy harvesting clothing, medical devices, soft robotics, and other use-based applications. Fabrication and characterization occurs for multifunctional micro- and nano-scale materials using a cleanroom to perform research for devices such as semiconductor MEMS and smart sensors. Material characterization equipment includes instrumentation for metals, plastics, composites, and ceramics. Samples for examinations for microstructure and macrostructure are performed and linked to the fabrication processes and determine the properties for engineered materials. Nondestructive Testing and Evaluation (NDT) is performed while maintaining component integrity. Aspects of NDT for advanced manufacturing also include in-line process and quality monitoring, noninvasive material characterization, and predictive and preventive maintenance.

Additive Manufacturing

Research in laser-based additive manufacturing occurs for metals in the development of new materials and design of complex structures using Additive Manufacturing (AM) also referred to as 3D printing. Design for AM, alloy development, parameter optimization, optimization of the laser melting process are all performed for applications including robotics and automation, lightweight structures, aerospace and other use-based applications. Performance of metal parts created by AM is characterized with testing and instrumentation since the parts are significantly different than conventionally manufactured parts. Additive manufacturing research of non-metal materials, includes photopolymer, engineering plastics, ceramics, and composites. Additional understanding of novel applications for additive manufacturing include examples from manufacturing to biosystems, bioprinting, and bio-scaffolding also undergo characterization of material properties.

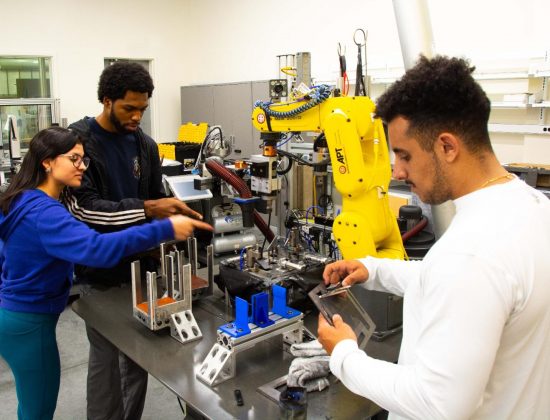

Plant Operations including Robotics and Automation

Operations research and statistical analysis techniques optimize processes with the goal is to improve these processes and production systems to enhance their performance centered on specific objectives. Instrumentation, sensors, data acquisition, and systems control are applied to use-based applied research for industry. Development of robotic technologies such as robotic manipulation, grasping, collaborative robotics, machine vision, and automatic inspection are applied to manufacturing for industry in the development of new robotics and automation manufacturing processes. Additional use-based applied projects include robotic manufacturing technologies for alternative energy systems, automation in agriculture, and other field robotics uses.

Resources

More information to come soon.

Last updated: 11/28/2022